Jacket Design

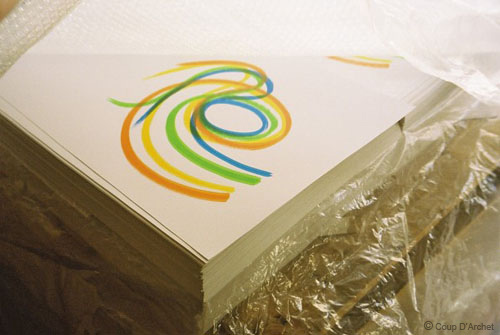

Some subscribes have shown interest in the process involved in the printing of the jackets. Despite the apparent simplicity of the design for AO3, the production of these jackets has entailed considerably more work than previous sets.

Some subscribes have shown interest in the process involved in the printing of the jackets. Despite the apparent simplicity of the design for AO3, the production of these jackets has entailed considerably more work than previous sets.

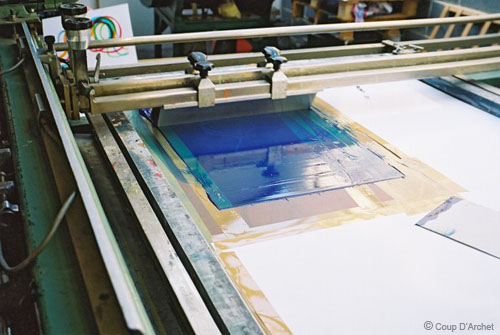

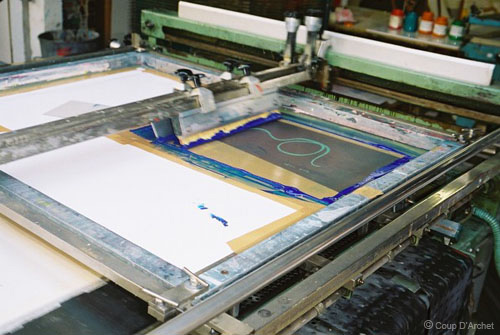

To begin with the design stage, each line was made in black ink on its own separate sheet of paper, each subsequent stroke being aligned with the former on a light box. This was in effect the 'colour separation'. From each sheet of paper was produced its own positive film, and from each film, its own screen. The transparent inks were, as ever, hand mixed and each line individually screened onto the card.

To achieve the ghosting effect, after the application of each colour had dried, the screen was shifted slightly and the line was printed again. So in the instances where there are six colours in the design, each sheet of card went through the process twelve times.

The title captions were printed separately (along with the catalogue numbers on the reverse), and again, to achieve depth of colour, the ink was applied twice. The INA blue, the AO gold and the black text were each again applied separately. So you will see that each sheet of card that makes each jacket has been through the printing stage up to 17 times.

If this had been produced by standard CMYK four colour photo-litho process each sheet would go through the press just once. Although a much faster (and cheaper) technique, the richness and subtle blending of the colours would be lost as would the texture and 'feel' of the ink application.

I hope the photographs below will provide both edification and amusement.